Aluminum trench boxes, also known as trench shields, are protective systems used in excavation and trenching activities to ensure the safety of workers. These boxes are designed to prevent cave-ins and collapses while working in trenches, offering a secure environment for laborers. Here are some key points about aluminum trench boxes:

Features and Benefits:

- Material: Made from lightweight aluminum, which makes them easier to handle and transport compared to steel trench boxes.

- Strength: Despite being lightweight, aluminum trench boxes provide substantial strength and support to withstand soil pressure and prevent trench collapses.

- Modular Design: Often come in modular designs, allowing for easy assembly and disassembly. This modularity enables customization to fit various trench sizes and shapes.

- Versatility: Suitable for a variety of applications, including utility work, pipe laying, and general excavation tasks.

- Corrosion Resistance: Aluminum is resistant to corrosion, making these trench boxes durable and long-lasting even in harsh environmental conditions.

- Ease of Use: Lightweight nature and modular design make them easy to install and reposition as needed, reducing labor costs and time.

- Compliance: Designed to meet safety standards and regulations set by organizations such as OSHA (Occupational Safety and Health Administration) to ensure worker safety in trenching operations.

Applications:

- Utility Work: Installing and repairing water, sewer, gas, and electrical lines.

- Construction: Creating foundations, installing drainage systems, and other construction activities.

- Maintenance: Ongoing maintenance of underground infrastructure.

Components:

- Panels: The main structural elements that provide protection. These come in various sizes to accommodate different trench dimensions.

- Spreaders: Adjustable or fixed-length components used to maintain the distance between the panels, ensuring the box stays open at the desired width.

- End Panels: Optional components that can be added to enclose the ends of the trench box, providing additional stability.

Safety Considerations:

- Inspection: Regular inspection of the trench box for any signs of wear, damage, or defects is crucial to ensure its effectiveness and safety.

- Proper Installation: Ensuring the trench box is properly installed and secured to provide maximum protection.

- Training: Workers should be adequately trained in the use and installation of trench boxes to ensure safety and compliance with regulations.

Aluminum trench boxes are an essential tool in the construction and utility industries, providing a safe and efficient way to protect workers during trenching operations.

Aluminum Trench Box Quote Form

Please call 336-516-8011 if you have any questions.

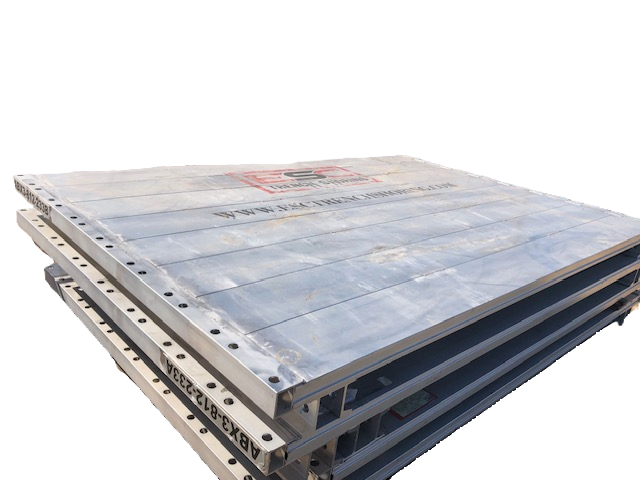

Aluminum Trench Boxes for Sale

| Product Code | Size (HxL) | Weight lb | Depth Rating | Price | Available | Updated |

|---|---|---|---|---|---|---|

| ABX3-68 | 6x8 | 1,031 | B45=25, C60=20, C80=18 | $6,500.00 | 2 | 1/13/2024 |

| ABX3-610 | 6x10 | 1,200 | B45=25, C60=20, C80=16 | $7,375.00 | 2 | 1/13/2024 |

| ABX3-812 | 8x12 | 1,823 | B45=21, C60=16, C80=13 | $9,750.00 | 2 | 1/13/2024 |

Modular Aluminum Panel Shields

Aluminum Modular Panel Shields (2′ tall stackable panels)

Aluminum Modular Panel Shields (2′ tall stackable panels)

Varying and Multiple Quantities Available

4′ Tall

4×4, 4×6, 4×7, 4×8, 4×10, 4×12

6′ Tall

6×4, 6×6, 6×7, 6×8, 6×10, 6×12

8′ Tall

8×4, 8×6, 8×7, 8×8, 8×10, 8×12

10′ Tall

10×4, 10×6, 10×8, 10×10, 10×12

Investing in an aluminum trench box not only enhances safety on construction sites but also improve overall efficiency. One of the key advantages is the lightweight nature of aluminum, making these trench boxes significantly easier to handle and transport compared to their steel counterparts. This feature not only simplifies on-site logistics but also reduces the need for heavy machinery during installation and removal.